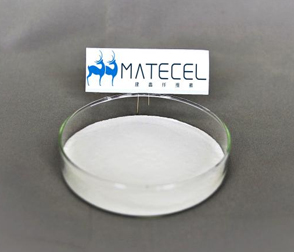

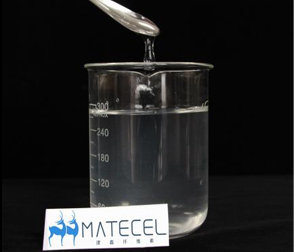

1.HPMC introduction

HPMC is a white powder and occasionally the color is light yellow. When it dissolves in water, it will form a colorless and transparent gel solution. Its main functions are to thicken and retain(lock) water. HPMC is usually used in mortar, tile adhesive, the daily chemical industry, and so on.

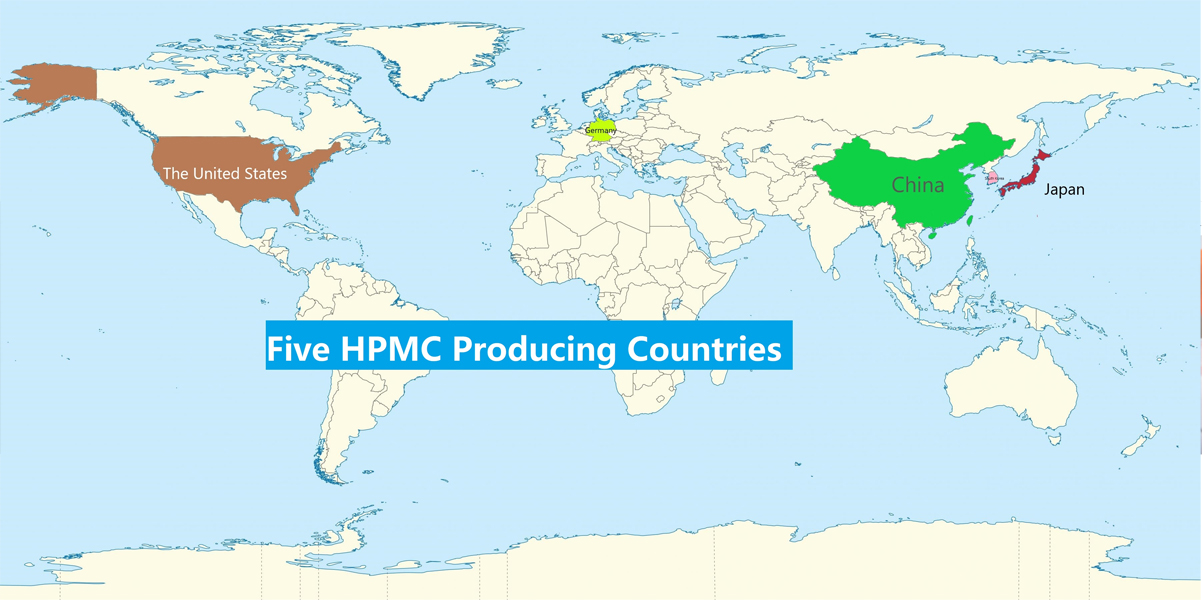

2. The Overview of the main producing and sales areas of HPMC

The United States, South Korea, Japan, Germany, and China are the main producing countries of HPMC, among which China is the only developing country producing highly cost-effective HPMC.

The main HPMC market is China, which accounts for about half of the entire market.

Indonesia and Vietnam occupy a large sales proportion in Southeast Asia.

Among the five countries in Central Asia, Uzbekistan has the largest consumption of HPMC.

In the middle east area, Turkey is an important market.

And Egypt mainly uses HPMC that can be dissolved in cold water for the daily chemical industry.

Economical HPMC, which is extremely cost-effective, is very popular in South Asia and India.

For the European market, it requires premium HPMC (good quality and good price) and it demands certificates verified by European Union.

South America is a very important HPMC market, of which Brazil has the largest demand; Chile mainly does transit trade.

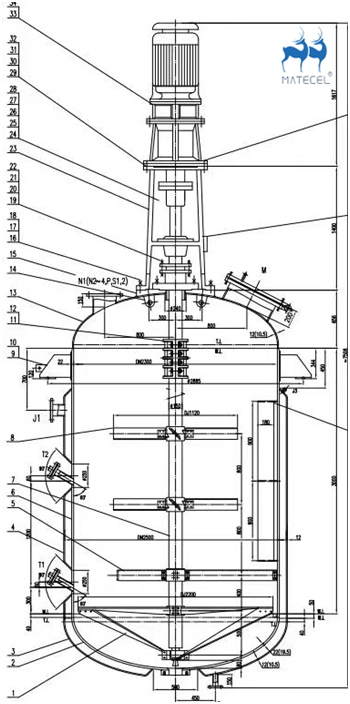

3. HPMC's production machines include vertical reactors and horizontal reactors. What are the differences between them?

The reactors for chemical production are generally closed containers. They can bear high temperatures and high pressure and perform chemical reactions.

The vertical reactor, as the name suggests, is vertical. It uses the solvent method, whose finished products have low viscosity, good transparency, and high degree of substitution.

Horizontal reactors are placed horizontally just as their name, which uses the gas phase method. And the HPMC produced here is of high viscosity, relatively low transparency and slightly low degree of substitution.

To help you understand better, the structural drawings and actual photos of the two reactors are shown below:

Vertical Reactor's Structure Drawing

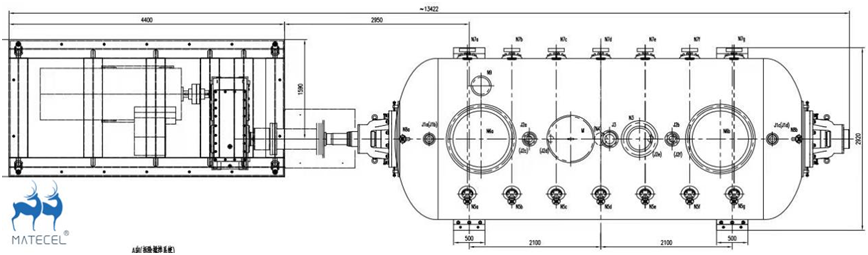

Horizontal Reactor's Structure Drawing

Vertical Reactors' Actual Photo

Vertical Reactors' Actual Photo

Put HPMC powder into hot water, which is generally around 70℃ to 80 ℃. When this aqueous solution’s own heat gradually cools down, with constant stirring, the aqueous solution will have a little viscosity, then you can stop stirring. Because when the aqueous solution is with viscosity, HPMC can be evenly suspended in water, and will not sink. The temperature of the aqueous solution at this moment is called the solution temperature in the chemical sense.

When HPMC is dissolved into water, it will become a colorless and transparent aqueous solution. Continuously heat the colorless and transparent aqueous solution up, until it turns to opaque opalescent colloid. At this point, the temperature is the gel temperature. It can also be simply to be understood as the lost efficacy temperature of cellulose. HPMC in the colorless transparent colloid plays the role of increasing water retention and other properties. Thus if it becomes a non-transparent, like milky liquid, HPMC will lose its effectiveness at this moment.

As to our GMK200Z model, its gel temperature is from 70℃ to 75℃. And its dissolution temperature is generally around 55℃ to 57 ℃, occasionally 50℃, or at other temperatures. As long as the dissolution temperature is not too low, it will not affect the formation of the aqueous solution of HPMC and the HPMC’s performance in the mortar. Therefore, the dissolution temperature is not a necessary indicator in China's national standards.

Generally, when the temperature of the aqueous solution is reduced to 55℃-57℃, the stirring can be stopped. Because at this moment the aqueous solution has a little viscosity, it can make HPMC suspend without sinking to the bottom.

However, the dissolution temperature of some products is relatively low, possibly 50 ° C. If the temperature of the aqueous solution is reduced to temperature 55℃-57℃ and the stirring is stopped, then at that moment, the aqueous solution has no viscosity, and the HPMC will not be suspended and thus will sink to the bottom.

To solve this problem you can continue stirring until the temperature drops to 50 ° C. Moreover, the water temperature on the site generally does not exceed 40 ° C, that is, it will be less than the dissolution temperature, then HPMC will become a colloid and function as it is supposed to be.

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Parque de Industria Química de Reciclado de Alta Tecnología, Pueblo de Xincheng, Ciudad de Xinji, Provincia de Hebei, China Código Postal

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. Reservados todos los derechos